- Next

- Prev

1950’s

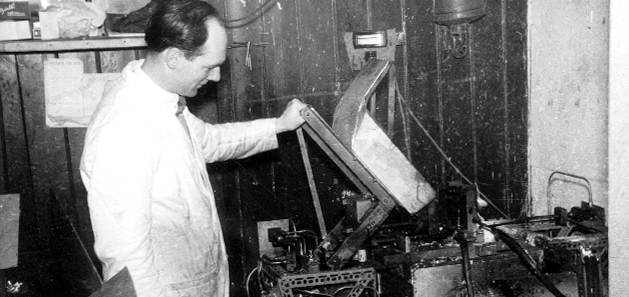

By the late 1950’s he had already developed his first prototype hollow pressure die casting machine.

- Next

- Prev

1960’s

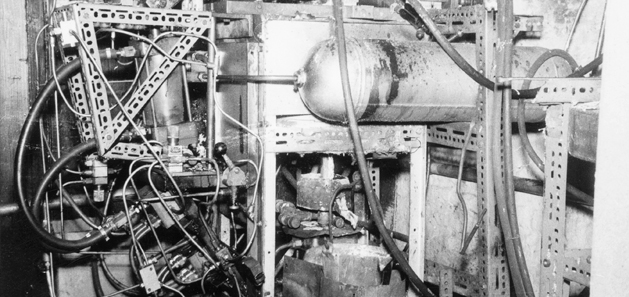

The first John Guest company was formed in the early 1960’s specialising in precision engineering and tool making.

1960’s

A second group company was established to concentrate on zinc die casting.

1960’s

Throughout the decade both engineering and die casting companies grew steadily.

1960’s

Both companies utilised the Grand Union Canal to assist in product distribution.

- Next

- Prev

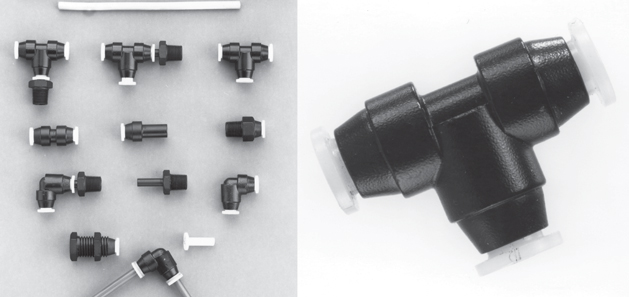

1970’s

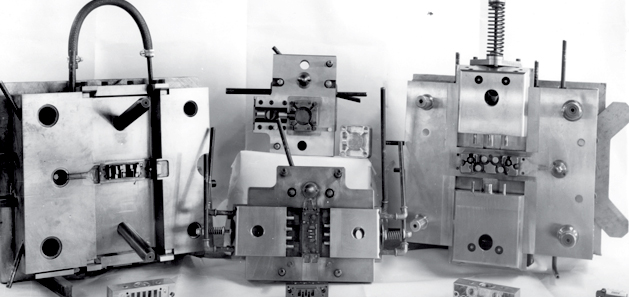

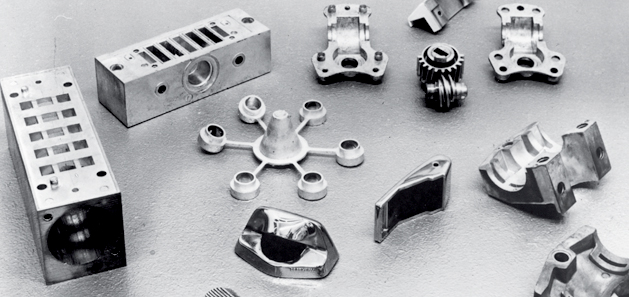

By 1971 John Guest was producing complex die cast items and machining for major UK pneumatic valve manufacturers. John Guest was becoming ‘vertically’ integrated from tool design, tool manufacture to production of die castings.

1970’s

By 1971 John Guest was producing complex die cast items and machining for major UK pneumatic valve manufacturers. John Guest was becoming ‘vertically’ integrated from tool design, tool manufacture to production of die castings.

1970’s

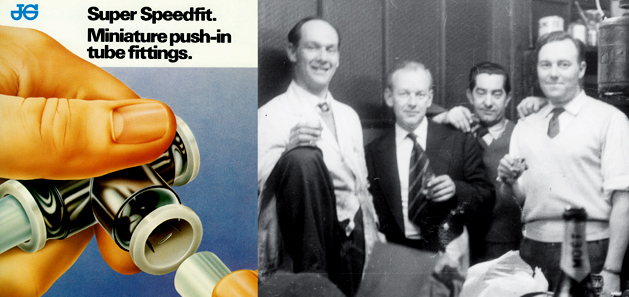

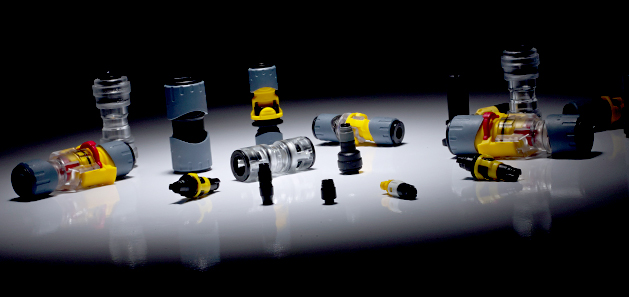

In 1974, John Guest developed his first push in tube connector for use with compressed air. That basic ‘Super Speedfit’ concept has been developed to include fittings for a wide range of applications.

1970’s

In 1974, John Guest developed his first push in tube connector for use with compressed air. That basic ‘Super Speedfit’ concept has been developed to include fittings for a wide range of applications.

1970’s

100’s of millions of fittings are now being used worldwide in industries as diverse as Automotive Compressed Air, Pneumatics, Drinks Dispense, Plumbing and Heating and Telecommunications.

1970’s

100’s of millions of fittings are now being used worldwide in industries as diverse as Automotive Compressed Air, Pneumatics, Drinks Dispense, Plumbing and Heating and Telecommunications.

1970’s

A second factory, covering 9,000 sq ft was opened in West Drayton.

1970’s

John Guest Limited was formed in 1978 specifically to market products designed and produced by the company, the organisation moving from sub contracting to becoming an own-product operation.

- Next

- Prev

1980’s

The company has always seen the world as its marketplace. Direct exports started in the early 1980’s and the first overseas sales company was founded in France in 1983.

1980’s

Other overseas companies followed, in New Zealand, the USA and Italy, and within a decade,exports accounted for over 50% of total output.

1980’s

Other overseas companies followed, in New Zealand, the USA and Italy, and within a decade, exports accounted for over 50% of total output.

1980’s

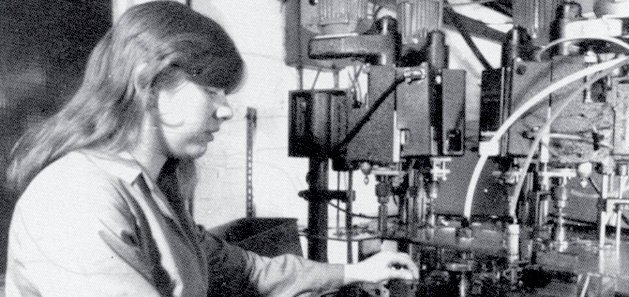

The 1980’s was a period of great expansion and of exciting developments.

1980’s

The 1980’s was a period of great expansion and of exciting developments.

1980’s

The 1980’s was a period of great expansion and of exciting developments with the company working on both sides of the Grand Union Canal.

1980’s

The first food quality product range was launched in 1983, followed a year later by John Guest plastic fuel connectors being adopted by the Ford Motor Company.

1980’s

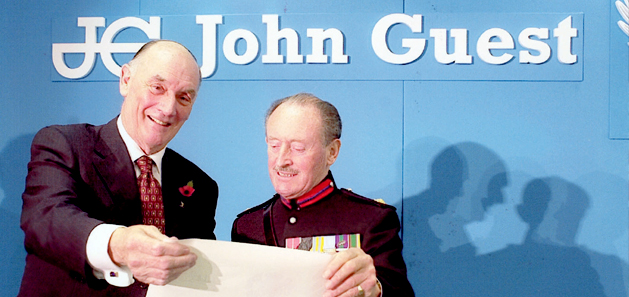

In 1982 John Guest was proud to receive an MBE for his services to industry. This was followed by the Horner’s Award in 1985, presented for ‘imaginative and appropriate use of plastics’.

1980’s

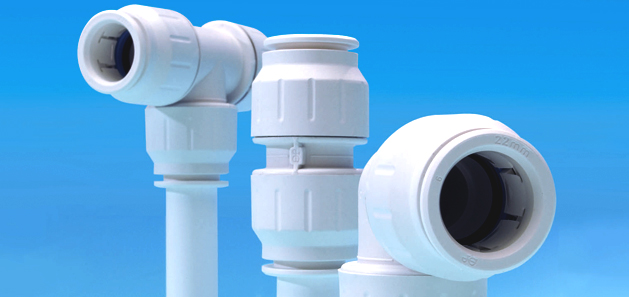

The Speedfit Plumbing and Heating System was launched in 1987 at the Interbuild Exhibition and wins best new product at the show award.

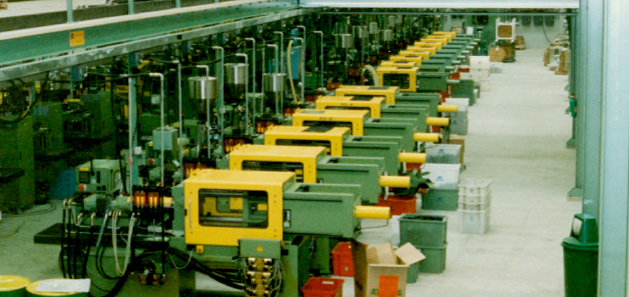

1980’s

Expansion of staff and production meant that the company had to move, in 1989 to a new purpose designed factory of around 61,000 sq feet.

1980’s

Expansion of staff and production meant that the company had to move, in 1989 to a new purpose designed factory of around 61,000 sq feet.

- Next

- Prev

1990’s

The first Queen’s Award for Export Achievement was received in 1990, followed by a second such Award in 1995. Exports accounted for 53% of total sales.

1990’s

In expanding overseas, sales and distribution operations were opened in Germany, Spain and Australia.

1990’s

The German company moving to larger premises by the end of the decade to take advantage of the emerging markets of eastern Europe.

1990’s

In 1998, the company opened its factory in Maidenhead, specialising in the extrusion of pipe and tube.

1990’s

The company’s commitment to quality was recognised by the receiving of the British Standard Kitemark Award for Plumbing Fittings and Pipe.

1990’s

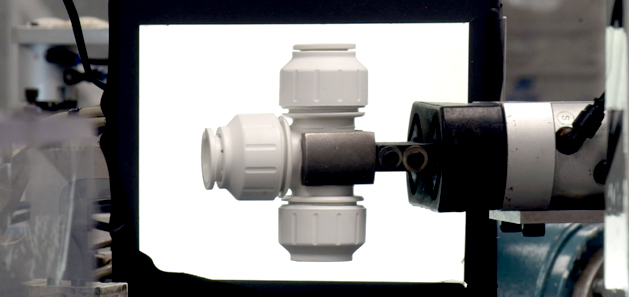

By now, there were over 2,000 different types and sizes of fittings in the product range.

- Next

- Prev

2000’s

John Guest enjoyed a great start to the millennium, receiving its third Queen’s Award for International Sales.

2000’s

A new 32,000 sq ft distribution centre was opened in Hayes, West London.

2000’s

In 2002, the company was awarded its ISO14001 environmental standards certification.

2000’s

The commitment to product development was recognised by the receiving of the Queen’s Award for Innovation, recognising the development of Twist and Lock Plumbing Fittings and Pipe.

2000’s

The commitment to product development was recognised by the receiving of the Queen’s Award for Innovation, recognising the development of Twist and Lock Plumbing Fittings and Pipe.

2000’s

In 2003, John Guest continued expanding its production capacity by opening a further moulding factory in Cornwall, UK. Further expansion saw the opening of sales offices in Korea, Czech Republic.

2000’s

John Guest also purchased a premises at an established commercial location in Bracknel, UK which comprises of over 65,500sq feet of warehouse space.

- Next

- Prev

2010’s

In 2011 JG celebrated its 50th year, a proud milestone for a company that prides itself on engineering legacy.

2010’s

The Blown Fibre range for the telecommunication market grew with the addition of a variety of connector concepts. Innovative additions include fittings to aid in direct buried environments and gas and water blocking connection technology.

2010’s

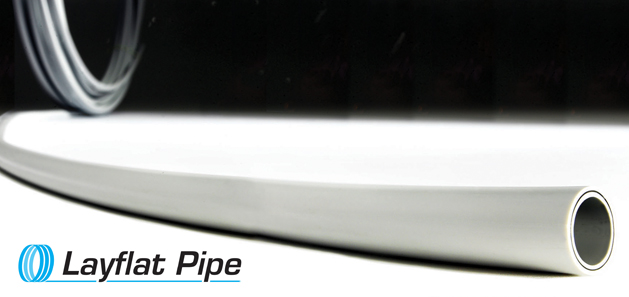

In 2012 JG Speedfit launched Layflat Polybutylene barrier pipe which offered greater flexibility making the Speedfit system even more easy to handle and worry free.

2010’s

February 2014 saw the official opening of a new purpose built warehouse in New Zealand. The warehouse is twice as large as its predecessor and contains a show room and training facilities.

2010’s

September 2014 saw the launch of JG Aura, the new heating control concept that gives complete control of your home heating from the palm of your hand.

2010’s

In 2018, John Guest joined the RWC’s family of brands. And today, RWC stands as the world’s leading plastic and metal push-fit fittings, pipe and valves manufacturer.

2010’s

In 2018 and 2019, JG Speedfit secured the Best Plumbing Brand title at the BMJ Industry Awards for two years in a row.